NON-Glass HANDMADE marbles

Please note that most of the information on this page is borrowed from the writings of Jeff Carskadden and Richard Gartley, both of whom have heavily researched this topic and are gratefully thanked for helping advance the hobby of marble collecting into the realm of professional archaeology. - A. Basinet

AGATES

Hand cut agates were mostly produced in the Idar-Oberstein area of western Germany at least as early as 1775 and probably much earlier. However, the peak period of production was in the 1880s. Agate was mined from Idar-Oberstein for centuries and evidence for actual agate mills dates to as early as 1454. By 1775 there were 26 agate mills in the region.

In 1802, to counter the dwindling supply of locally procurable semi-precious stones, agate was begun to be imported to Idar-Oberstein from India. Then in 1827, agate was discovered in Uruguay (in a region that is now part of Brazil), and thereafter (beginning around 1834) this agate was exported to Idar-Oberstein.

The agate marble market thrived after 1860 and continued until the onset of World War I. Many of these marbles were shipped to the United States during this period. After the great war, the industry was seriously crippled, not only because of the war but likely resulting from the growing popularity of machine made glass marbles, which were initially given names to suggest their similarity to "aggies." Hence, such companies as Akro Agate and Christensen Agate. Though some hand cut German agates were distributed in small Master Marble boxes at the 1934 Chicago World's Fair, production of these marbles had effectively ceased around 1925.

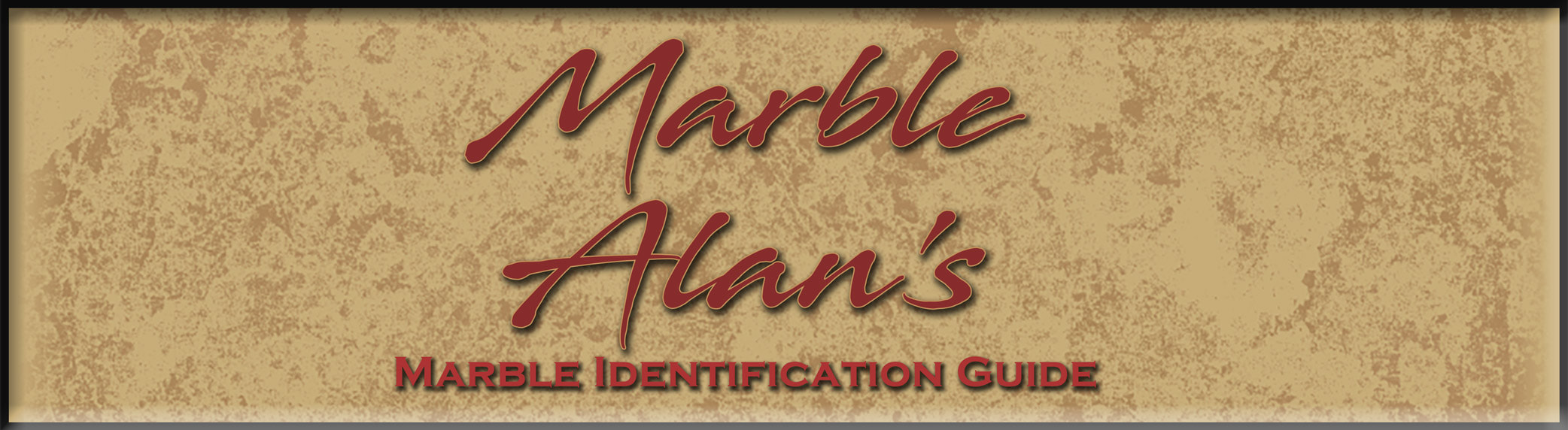

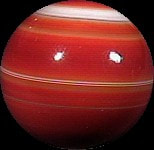

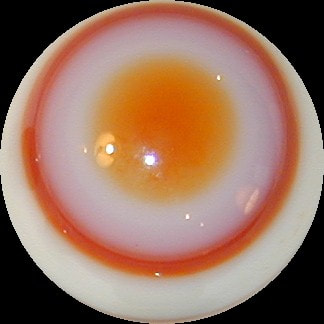

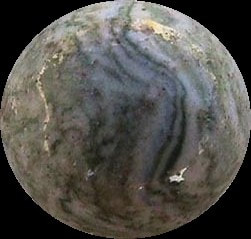

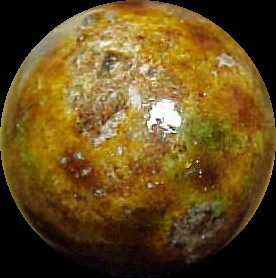

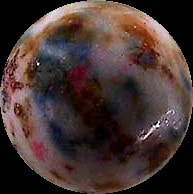

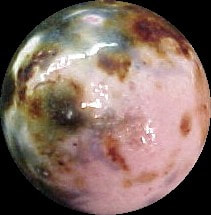

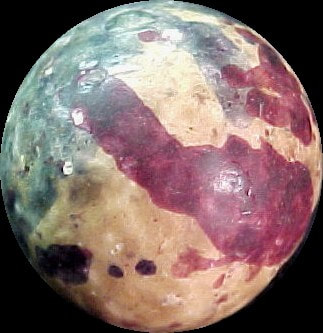

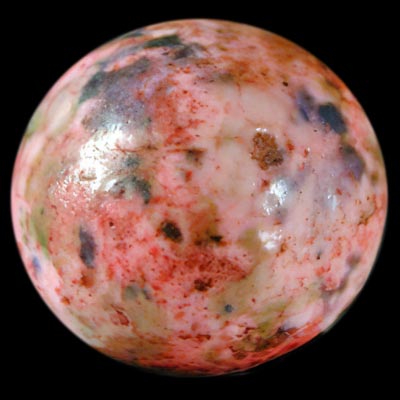

Agates are composed of chalcedony, a fibrous quartz, that formed concentric layers (bands), mostly in lava flows. Mineral impurities in these layers give the stone various natural colors, usually shades of red and brown. Specific names have been applied to agate marbles, depending on their color. Carnelian agates are red to reddish brown, striped carnelian agates have alternating red and white bands, onyx agates are black, and striped onyx agates have alternating black and white bands. There are other types of agates, too. Dendritic agates possess "fern-like" patterns in an otherwise gray matrix, while moss agates have intertwined hair-like fibers. Both of these patterns are formed by mineral impurities.

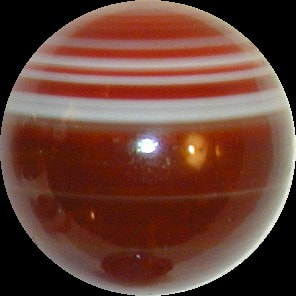

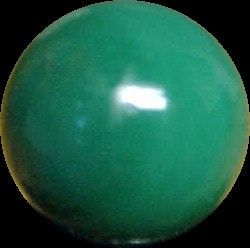

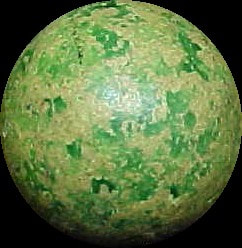

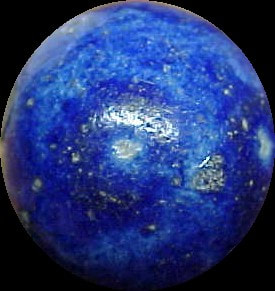

However, most banded agates from Idar-Oberstein were heated and/or dyed to create their banding effect, due to the fact that after 1834 a lot of the stone used for the marbles was translucent bluish-gray South American agate. It was long known in Idar-Oberstein that otherwise plain agates would become red when exposed to long periods of sunlight. Therefore, after 1813 agate workers began heating the agates in ovens to achieve the same effect. This heating changed the color in the stone because the ferric oxide impurities would react to the high temperature. Soon thereafter, the workers realized that a reddish color could also be achieved by immersing the marbles in iron nitrate or iron vitriol solutions. The black color in some agates was effected by boiling that agate in a sugar solution or soaking it in honey, and then treating it with sulfuric acid. Black dyed agates was an idea introduced from India around 1819. Less commonly, some agates were dyed blue, green, or yellow, and this apparently was done only after 1845.

Agates were made by first chipping small cubes of stone from a larger piece of material. Then, the stone was ground down by workers who had to lie on their stomachs across a sloping board, with their feet braced against pieces of wood attached firmly to the floor. This position allowed the workers to face the millstone and exert the considerable force needed to grind the stone. The millstone itself was made of sandstone and measured around five feet in diameter. It was kept moving by a water wheel attached to a set of cogwheels to quicken the number of revolutions.

Hand cut agates are typically faceted, as they were ground by hand into spheres. However, following this procedure they were placed into polishing drums, and depending upon the amount of time they spent in these drums the facets could be completely removed, or might remain mostly intact.

Machine ground agates, on the other hand, never have facets, though this too cannot be used as a trait to date agates. Again, some hand ground agates will lack faceting, and will appear to be machine ground. Conversely, some people still hand grind agates avocationally, so just because an agate manifests facets does not necessarily mean it is old.

There are many other types of semiprecious stone that can be placed in the agate category. However, most (but not all) of these are modern and machine ground. These minerals may include malachite, tigereye, rose quartz, amethyst, onyx, bloodstone, and rhodenite, among others.

Hand cut agates were mostly produced in the Idar-Oberstein area of western Germany at least as early as 1775 and probably much earlier. However, the peak period of production was in the 1880s. Agate was mined from Idar-Oberstein for centuries and evidence for actual agate mills dates to as early as 1454. By 1775 there were 26 agate mills in the region.

In 1802, to counter the dwindling supply of locally procurable semi-precious stones, agate was begun to be imported to Idar-Oberstein from India. Then in 1827, agate was discovered in Uruguay (in a region that is now part of Brazil), and thereafter (beginning around 1834) this agate was exported to Idar-Oberstein.

The agate marble market thrived after 1860 and continued until the onset of World War I. Many of these marbles were shipped to the United States during this period. After the great war, the industry was seriously crippled, not only because of the war but likely resulting from the growing popularity of machine made glass marbles, which were initially given names to suggest their similarity to "aggies." Hence, such companies as Akro Agate and Christensen Agate. Though some hand cut German agates were distributed in small Master Marble boxes at the 1934 Chicago World's Fair, production of these marbles had effectively ceased around 1925.

Agates are composed of chalcedony, a fibrous quartz, that formed concentric layers (bands), mostly in lava flows. Mineral impurities in these layers give the stone various natural colors, usually shades of red and brown. Specific names have been applied to agate marbles, depending on their color. Carnelian agates are red to reddish brown, striped carnelian agates have alternating red and white bands, onyx agates are black, and striped onyx agates have alternating black and white bands. There are other types of agates, too. Dendritic agates possess "fern-like" patterns in an otherwise gray matrix, while moss agates have intertwined hair-like fibers. Both of these patterns are formed by mineral impurities.

However, most banded agates from Idar-Oberstein were heated and/or dyed to create their banding effect, due to the fact that after 1834 a lot of the stone used for the marbles was translucent bluish-gray South American agate. It was long known in Idar-Oberstein that otherwise plain agates would become red when exposed to long periods of sunlight. Therefore, after 1813 agate workers began heating the agates in ovens to achieve the same effect. This heating changed the color in the stone because the ferric oxide impurities would react to the high temperature. Soon thereafter, the workers realized that a reddish color could also be achieved by immersing the marbles in iron nitrate or iron vitriol solutions. The black color in some agates was effected by boiling that agate in a sugar solution or soaking it in honey, and then treating it with sulfuric acid. Black dyed agates was an idea introduced from India around 1819. Less commonly, some agates were dyed blue, green, or yellow, and this apparently was done only after 1845.

Agates were made by first chipping small cubes of stone from a larger piece of material. Then, the stone was ground down by workers who had to lie on their stomachs across a sloping board, with their feet braced against pieces of wood attached firmly to the floor. This position allowed the workers to face the millstone and exert the considerable force needed to grind the stone. The millstone itself was made of sandstone and measured around five feet in diameter. It was kept moving by a water wheel attached to a set of cogwheels to quicken the number of revolutions.

Hand cut agates are typically faceted, as they were ground by hand into spheres. However, following this procedure they were placed into polishing drums, and depending upon the amount of time they spent in these drums the facets could be completely removed, or might remain mostly intact.

Machine ground agates, on the other hand, never have facets, though this too cannot be used as a trait to date agates. Again, some hand ground agates will lack faceting, and will appear to be machine ground. Conversely, some people still hand grind agates avocationally, so just because an agate manifests facets does not necessarily mean it is old.

There are many other types of semiprecious stone that can be placed in the agate category. However, most (but not all) of these are modern and machine ground. These minerals may include malachite, tigereye, rose quartz, amethyst, onyx, bloodstone, and rhodenite, among others.

AGATES GALLERY

(Hover your mouse or lightly touch the image to see the type of marble. Click to view the full size image)

(Hover your mouse or lightly touch the image to see the type of marble. Click to view the full size image)

ALABASTERS

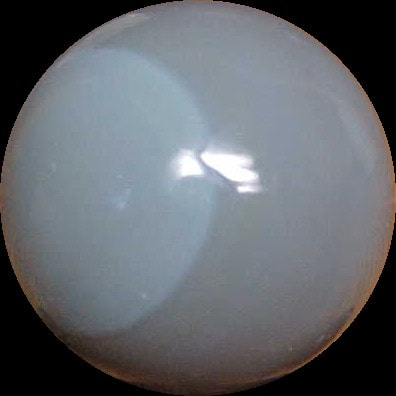

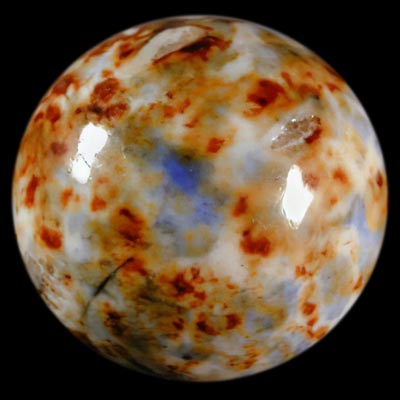

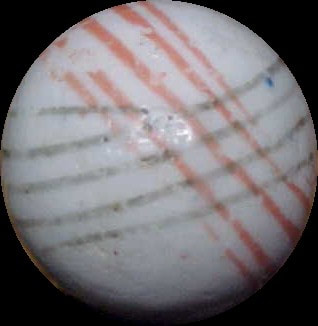

Alabaster marbles are made from real marble and originate primarily from the Berchtesgaden-Salzburg region of Germany, where they were made chiefly after around 1790. Marble mills were operating in this region no later than 1680. Here, the marble was mined primarily from Untersberg Mountain, though some came from near the town of Oettingen; this latter marble is called Hochhaus. The marble mills in this region continued operating commercially until the beginning of the twentieth century, and in fact some still operate today as tourist attractions. The annual production is low, around 500-2000 pieces.

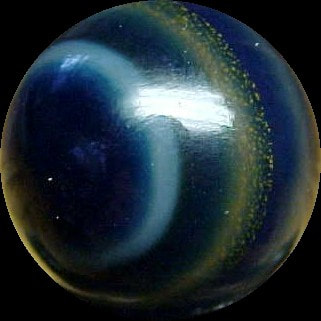

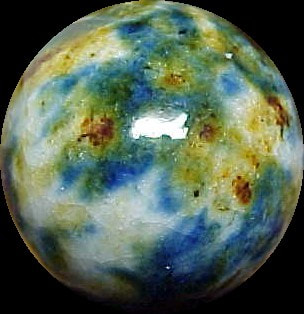

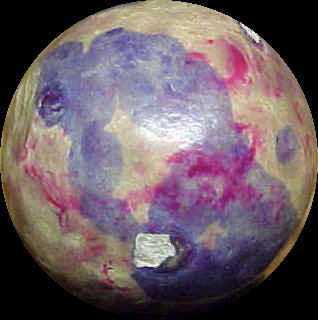

Most alabasters, or marble marbles, are composed of a white to light pink material with reddish veins. Some are of a grayish, yellowish, black, or red material, though. Though the term "alabaster" is something of a misnomer, as true alabaster is comprised of gypsum, the use of the term to refer to any stone containing banded calcite has been popularized by sculptors, architects, and the like. The term was adopted by marble players, and from this we get the term "alley" (hence the company Alley Agate).

Marble marbles are comprised of a softer material than the quartz agates. Therefore a different method was used to produce them. First, the parent material was cut into appropriately sized cubes. Then these cubes were placed into grooves in sandstone grindstones through which water was forced, turning the marble until it was smoothed into a perfect sphere. This process consumed as little as fifteen minutes, and therefore a single marble mill could produce thousands of these marbles each day.

Alabaster marbles are made from real marble and originate primarily from the Berchtesgaden-Salzburg region of Germany, where they were made chiefly after around 1790. Marble mills were operating in this region no later than 1680. Here, the marble was mined primarily from Untersberg Mountain, though some came from near the town of Oettingen; this latter marble is called Hochhaus. The marble mills in this region continued operating commercially until the beginning of the twentieth century, and in fact some still operate today as tourist attractions. The annual production is low, around 500-2000 pieces.

Most alabasters, or marble marbles, are composed of a white to light pink material with reddish veins. Some are of a grayish, yellowish, black, or red material, though. Though the term "alabaster" is something of a misnomer, as true alabaster is comprised of gypsum, the use of the term to refer to any stone containing banded calcite has been popularized by sculptors, architects, and the like. The term was adopted by marble players, and from this we get the term "alley" (hence the company Alley Agate).

Marble marbles are comprised of a softer material than the quartz agates. Therefore a different method was used to produce them. First, the parent material was cut into appropriately sized cubes. Then these cubes were placed into grooves in sandstone grindstones through which water was forced, turning the marble until it was smoothed into a perfect sphere. This process consumed as little as fifteen minutes, and therefore a single marble mill could produce thousands of these marbles each day.

ALABASTERS GALLERY

(Hover your mouse or lightly touch the image to see the type of marble. Click to view the full size image)

(Hover your mouse or lightly touch the image to see the type of marble. Click to view the full size image)